By Jim Dickson | Contributing Writer

Americans have a love affair with 4-inch blade drop point knives but the Morakniv Companion Heavy Duty has some serious advantages.

The style in question is the slab handle, hollow ground, super hard, wide 4-inch drop point blade knife. Back in the 1960’s when the custom knife market began to take off you had two types of knife makers. The traditional blacksmith type that forged blades and the newcomers who had discovered that you could just grind a knife out on a belt sander. One of the latter came up with the cheapest knife possible to make. The blade was hollow ground because that is what occurs when you clamp a blade blank in a jig and push it against the wheel of a big Bader belt sander.

The problem with that is that a hollow ground blade is prone to chip in use. They also do not hold an edge as well as a flat or convex grind. Just put a hollow ground knife on a kitchen cutting block, bear down on it and drag the edge across the block. You will notice under close inspection that the edge is shimmying and shaking as it is drawn over the block breaking its edge off as it goes. A flat or convex grind does not do that. Being ground from the back there were no straight bevel lines on the blade to show skill in grinding them. All of the cost savings were pocketed instead of being passed along to the customer.

In order to advertise how long they would hold an edge the blades were excessively hardened to the point that one of these broke when dropped on a kitchen linoleum floor. A hollow ground over hardened knife is the easiest of all blades to have chip and break in hard use. Sharpening these in the field was difficult.

Their wide blades made it hard to make the fine cuts normally expected of a 4-inch blade. They are a poor choice for caping or dressing small game, trout, and birds. Since they are custom knives they cost a lot. The makers do not pass on the savings they acquire from making the cheapest and easiest knife that they can so these cost as much as traditionally constructed knives which are harder to make.

I remember the late Elmer Keith telling me how much he disliked these knives and how they were only good for ripping. Keith was considered the dean of American gun writers in those days. He was an old cowboy and bronc buster who had lived through the last days of the old West in Idaho. He did a lot of hunting and guiding other hunters where he got plenty of experience in using knives in the field.

The knife makers and knives in question are now history but unfortunately, due to all the publicity they received in their day, they still unduly influence knife makers today.

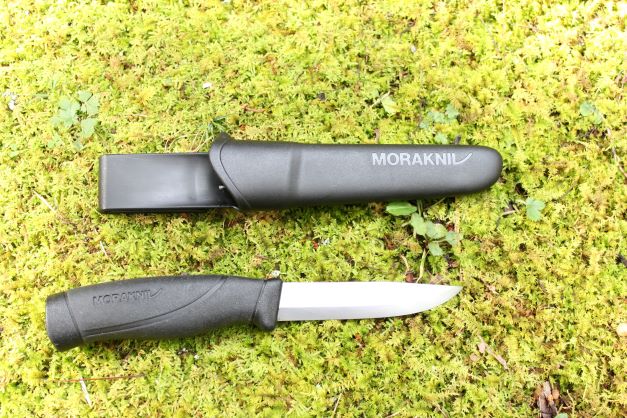

Now let’s look at the Swedish Morakniv Companion Heavy Duty, a knife with a MSR price of $24.99. This is a well-proportioned 4-inch blade knife with a ¾ inch wide blade perfectly suitable for fine cuts when dressing game of all sizes. It works splendidly as a small game, trout, and bird knife and is well suited for caping work. A narrow blade is necessary to get the full use out of a 4-inch blade as that narrow blade is its advantage over larger knives whose broader blades can’t make the fine turns in cutting a ¾ inch wide blade can. To clean birds and small game with a wide blade is awkward.

The Companion Heavy Duty has a TPE rubber handle that is carefully contoured for comfortable use over long periods of time while it’s 4.76-ounce weight does not tire the hand on a long hard job. Scandinavian knives are famous for their comfortable grips and this is a fine example. This handle has a pronounced swelling at the end of the handle instead of a guard. It should be noted that Scandinavians typically hold a knife tight in their fist when cutting and this shape locks into that grip precisely.

The blade is 3.2MM thick or .128 inches. The blade shape cannot be improved upon for a knife of this size. It is not intended to be an axe or a machete and certainly not a pry bar or a log splitting maul. It is designed to be everything a 4-inch blade knife can be and perform its work perfectly.

It is available in either carbon or stainless steel. The carbon steel is C100, a 1% carbon tool steel. The stainless steel version uses Sandvik 12C27 stainless steel with .6 carbon content hardened and tempered to Rockwell 55.5 to 57.5 on the Rockwell C scale which is as good a knife hardness as you can get. It holds an edge well yet it can still be touched up readily in the field.

Either the carbon steel or the stainless steel version will flex as far as anyone can reasonably expect. They certainly are not going to break if you drop them on a kitchen floor. If you are dressing out a deer you suddenly have no tool. If you are deep in the wilderness and your knife breaks your very survival is threatened.

This is why I look askance at people using the blade as a pry bar, or opening cans, and pushing to the limits of the knife and beyond. When something is as important to your survival in the wilderness as a knife is you should be babying it and not abusing it. Still, stuff happens and it is important that a blade be resilient.

It should be noted that the 420 HC steel used in many high priced factory knives has only .45 carbon content. That’s .15 less carbon than the .6% of the Sandvik 12C27 stainless steel which was designed with cutlery use in mind unlike the 420 HC which started out as virtually carbon free 420 stainless steel designed for easy fabrication which then had some carbon added when people started using it for knives because it was an easy to work with stainless steel.

The blade has the traditional Scandinavian grind which holds an edge well and is not prone to chipping like a hollow ground edge is. It also has a good sharp point. When you are making fine cuts carving or dressing game you need to be able to insert the knife easily and precisely. That means a good point is a necessity for fine work.

The narrow ¾ inch wide blade is also critical for fine turns when dressing out game. In Scotland field dressing a deer is called “graloching” and a good Scottish graloching knife will have a narrow blade so it can make the tight turns. A fat blade makes wide turns. When using it for small game, trout, and birds, anything wider is a serious handicap. Did you ever see a wide blade on a fillet knife? No, and you won’t because a fillet knife also has to make tight turns to do its job.

The sheath is the traditional Scandinavian style that swallows up much of the knife. It is made of plastic and has drain holes at the bottom. This is a rugged sheath that will protect you if you fall on the knife far better than most leather sheaths will once the leather gets water soaked. It snaps over the belt and this feature also makes it easy to carry in your pocket for the sheath will snap over the outside of your pocket flap just like the belt clip on an oversize pocketknife.

The Morakniv Companion HD also weighs a lot less than a big lock blade yet it is stronger and will do more work. Also it can never close on your fingers like a folding knife can. That and the more comfortable grip are among the reasons Scandinavians prefer fixed blade knives. In most places it is legal to carry a fixed blade knife of the same blade length that is legal for a folding knife.

Back when my wife, Betty and I had Alaskan trapper’s licenses there was a man trying to work on a frozen moose carcass with a big lock blade folder. Now this is a job for a saw or an axe yet he was using his folder as an icepick trying to chip away at the frozen carcass. The first time the force of the blow was in the direction the knife folds it folded and took off all his fingers due to the force of the blow he had directed at the frozen carcass. I never looked at folding knives the same way again. The lock of a lock blade knife is very weak to begin with. Fix the blade in the jaws of a vise and bear down on the handle and you will be amazed at how little force it takes to overcome the lock. Just don’t have your fingers around the handle when you do this. Also any grit or dirt from your pocket in the locking lug on the folder will keep the lock from fully engaging making the joint even weaker. This can’t happen with a fixed blade sheath knife.

So there you have it. The $25 Morakniv Companion Heavy Duty does the work expected of a 4-inch blade knife better than the expensive wide blade hollow ground slab handle custom knife that costs many times more money. It also does more work and is a lot safer to use than a folding knife of its size.